Understanding the Functionality and Application of a Manifold Absolute Pressure Sensor with a 3-Bar Range

Related Articles: Understanding the Functionality and Application of a Manifold Absolute Pressure Sensor with a 3-Bar Range

Introduction

In this auspicious occasion, we are delighted to delve into the intriguing topic related to Understanding the Functionality and Application of a Manifold Absolute Pressure Sensor with a 3-Bar Range. Let’s weave interesting information and offer fresh perspectives to the readers.

Table of Content

Understanding the Functionality and Application of a Manifold Absolute Pressure Sensor with a 3-Bar Range

The manifold absolute pressure (MAP) sensor is a crucial component in modern internal combustion engine management systems. This article explores the operation and significance of a specific type: the sensor with a 3-bar pressure measurement range. This type of sensor offers increased precision and a broader operational scope compared to sensors with lower pressure ranges. Its enhanced capabilities contribute significantly to optimized engine performance, fuel efficiency, and reduced emissions.

Operational Principles

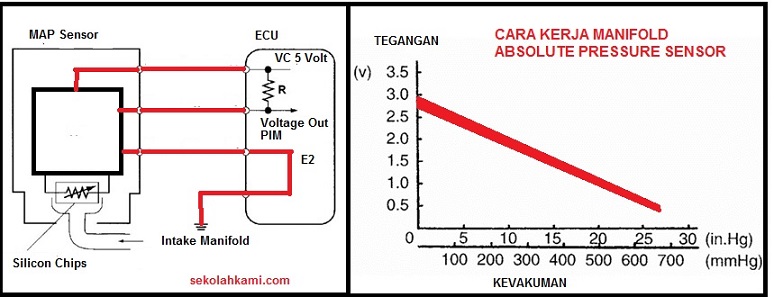

This sensor, often a silicon-based piezoresistive device, measures the absolute pressure within the engine’s intake manifold. This pressure reflects the air density entering the engine, a key factor in determining the appropriate fuel-air mixture for combustion. The sensor’s internal circuitry converts the pressure variations into a corresponding electrical signal, typically a voltage or frequency. This signal is then transmitted to the engine control unit (ECU).

The 3-bar pressure range signifies the sensor’s capacity to accurately measure pressures from vacuum (below atmospheric pressure) up to three times atmospheric pressure. This wide range allows for accurate measurements across a broad spectrum of engine operating conditions, including idle, acceleration, and high-altitude operation. The increased range is particularly beneficial in applications with turbocharged or supercharged engines, where boost pressure significantly increases manifold pressure.

Signal Processing and ECU Integration

The ECU receives the sensor’s signal and utilizes this data, along with other inputs such as engine speed, throttle position, and air temperature, to calculate the precise amount of fuel required for optimal combustion. The ECU’s sophisticated algorithms compensate for variations in atmospheric pressure and temperature, ensuring consistent fuel delivery and engine performance across diverse environmental conditions. The accuracy of the MAP sensor signal directly impacts the precision of these calculations. An inaccurate signal can lead to poor fuel economy, rough idling, misfires, and increased emissions.

Benefits of a 3-Bar Pressure Range

The extended measurement range of this sensor offers several advantages:

-

Enhanced Accuracy in Turbocharged/Supercharged Applications: Turbocharged and supercharged engines generate significantly higher manifold pressures than naturally aspirated engines. A 3-bar sensor accurately measures these elevated pressures, enabling precise fuel control and maximizing power output while minimizing emissions.

-

Improved Fuel Efficiency: Accurate fuel delivery, facilitated by the precise pressure readings, contributes to optimized combustion and improved fuel economy. The sensor’s wide range ensures accurate measurements even under demanding conditions.

-

Wider Operational Altitude Range: At higher altitudes, atmospheric pressure decreases. A 3-bar sensor maintains accurate measurements, ensuring optimal engine performance even at significantly reduced atmospheric pressures.

-

Enhanced Emission Control: Precise fuel metering, a direct consequence of accurate pressure sensing, minimizes unburnt fuel and harmful emissions, contributing to environmental compliance.

-

Improved Engine Performance: The precise control over the air-fuel mixture, enabled by the sensor, results in smoother engine operation, improved throttle response, and enhanced overall performance.

Frequently Asked Questions

-

Q: What happens if the 3-bar sensor fails? A: Failure can result in a range of issues, from poor fuel economy and rough idling to engine misfires and a check engine light illumination. The specific symptoms depend on the nature of the failure (e.g., a short circuit, an open circuit, or an inaccurate reading).

-

Q: How often should this sensor be replaced? A: There’s no fixed replacement interval. Regular vehicle maintenance checks should include sensor diagnostics. Replacement is typically recommended when sensor readings are found to be inaccurate or when the sensor malfunctions.

-

Q: Can a 3-bar sensor be used in a naturally aspirated engine? A: Yes, it can. While not strictly necessary, it provides a higher level of accuracy and a wider operational margin compared to sensors with lower pressure ranges.

-

Q: How is the sensor calibrated? A: Calibration is typically performed during manufacturing. However, some ECU systems may allow for adjustments based on diagnostic data. This process is usually undertaken by trained technicians using specialized diagnostic equipment.

-

Q: What are the common causes of 3-bar sensor failure? A: Common causes include physical damage, exposure to extreme temperatures, electrical faults, and prolonged exposure to harsh environmental conditions.

Tips for Maintaining Optimal Sensor Performance

-

Regular Vehicle Maintenance: Adherence to the manufacturer’s recommended maintenance schedule is crucial for the long-term health of all engine components, including the MAP sensor.

-

Avoid Exposure to Excessive Heat: Prolonged exposure to high temperatures can degrade the sensor’s performance.

-

Proper Wiring and Connections: Ensure all electrical connections to the sensor are secure and free from corrosion.

-

Professional Diagnostics: If any issues with engine performance are suspected, consult a qualified technician for proper diagnostics to rule out sensor malfunction.

-

Genuine Replacement Parts: When replacement becomes necessary, use only genuine or equivalent high-quality replacement sensors to ensure accurate and reliable operation.

Conclusion

The manifold absolute pressure sensor with a 3-bar pressure range is a vital component in modern engine management systems. Its ability to accurately measure a wide range of pressures is crucial for precise fuel control, optimized engine performance, improved fuel efficiency, and reduced emissions. Regular maintenance and proper diagnostics are essential for ensuring its continued reliable operation and maximizing the benefits it provides. The sensor’s role in modern engine technology underscores its importance in achieving efficient and environmentally responsible vehicle operation.

Closure

Thus, we hope this article has provided valuable insights into Understanding the Functionality and Application of a Manifold Absolute Pressure Sensor with a 3-Bar Range. We appreciate your attention to our article. See you in our next article!